COB Industries Introduces V-Block For Small Diameter LN2 Pipe Freezing

June, 2013—COB Industries, the manufacturer of Qwik-Freeze® and Accu-Freeze® Pipe Freezing Systems for over 40 years, has just introduced the Accu-Freeze® V-Block which is an ingenious new pipe freezing tool designed for LN2 freezes on tube and pipe sizes from 1/4” to 1-1/4” diameter.

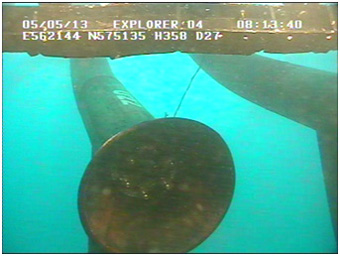

The patented Accu-Freeze® technology has been used extensively at several of the U.S. Navy’s prominent shipyards and on Nuclear Submarines for years and COB was approached about developing a faster, easier method of freezing small diameter pipe on Nuclear Subs and the new V-Block was the result.

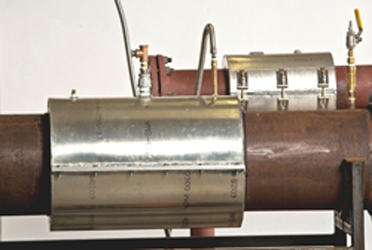

The V-Block is an amazingly simple and effective LN2 delivery system that can be used on various sizes of pipe.

The precision-machined stainless steel “block” is simply strapped onto the pipe and incorporates standard NPT fittings for LN2 intake and exhaust with a self-contained port to accommodate a thermocouple for reading the temperature of the pipe wall.

The V-Block can be used in conjunction with an Accu-Freeze® system (where the LN2 injections are automated and the temperature of the pipe wall is controlled with a programmed set-point) or it can just be used with standard LN2 tanks and cryogenic hoses.

The liquid nitrogen is pumped into the intake and circulated through the V-Block and vents from the exhaust, without coming in direct contact with the pipe. One of the key benefits of the V-Block design is that there is almost no set-up time required and it provides a freeze seal in the fastest manner possible.

It is also extremely cost-effective with a list price of just over $800.00 each.

If you would like more information or to schedule an interview, please contact Cletus O’Brien at (321) 723-3200 or email to sales@cob-industries.com