|  |  |  |

|  |  |  |

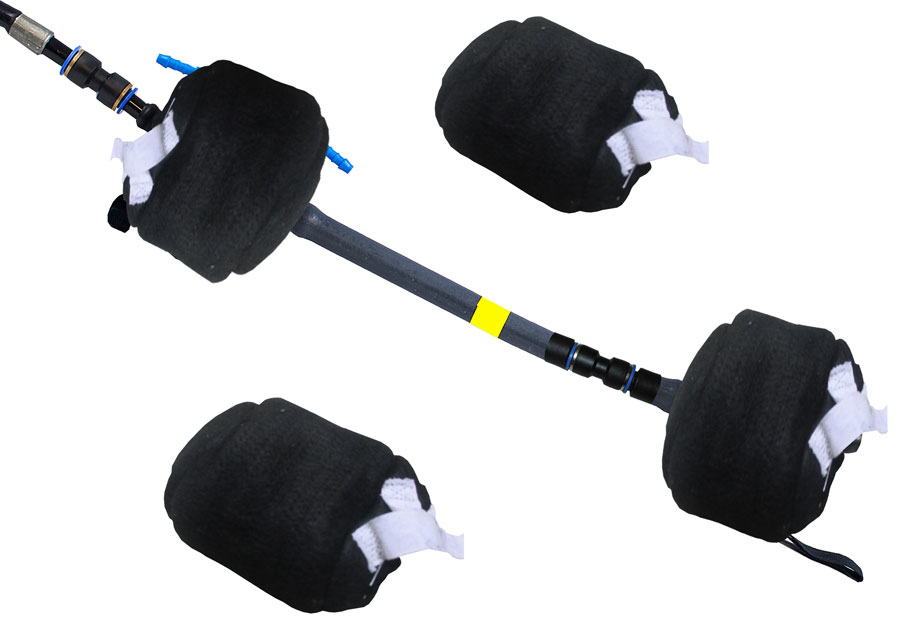

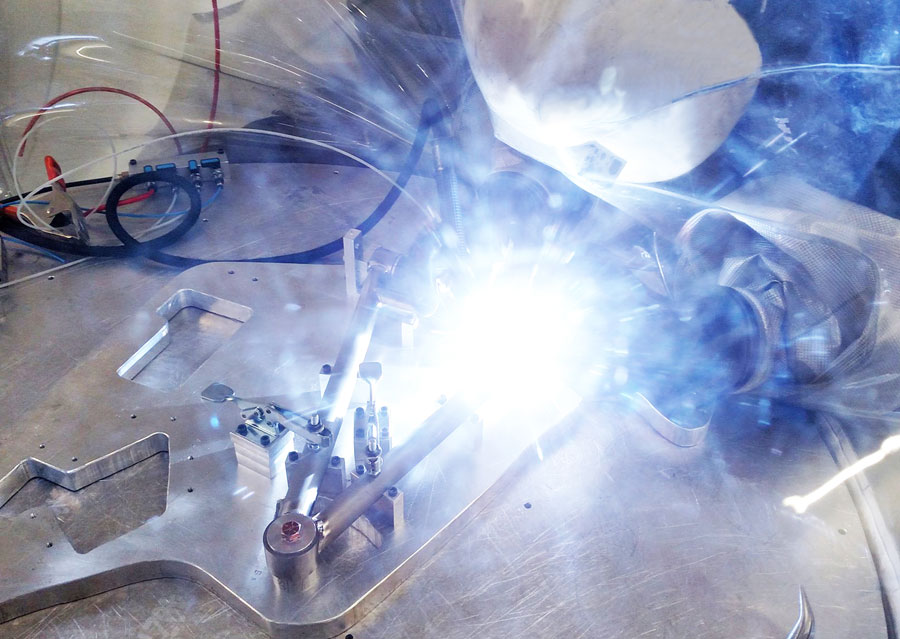

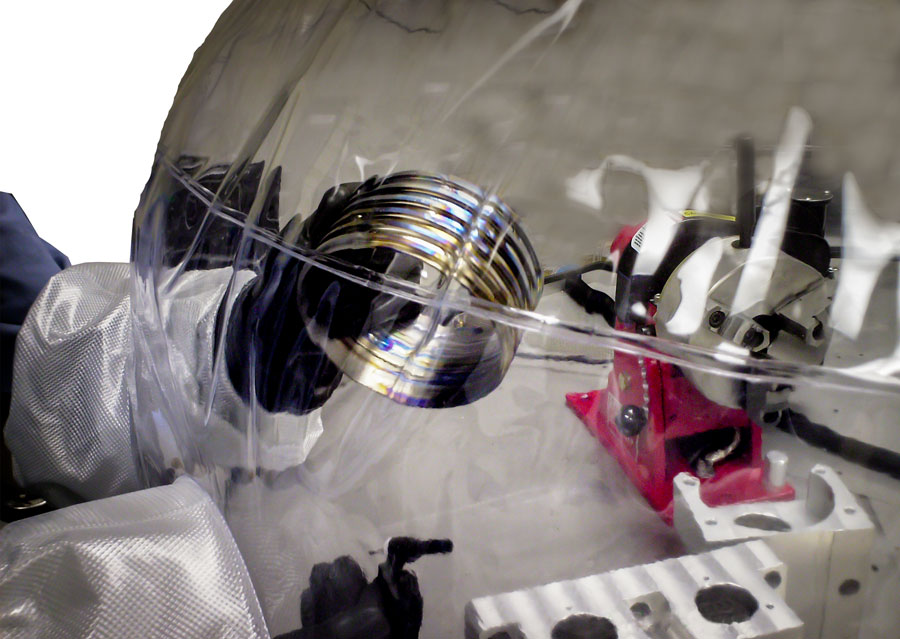

In May of 2022 a local mechanical contractor called with an urgent freeze requirement. The freeze was on the supply and return of a large chiller system. The chiller water was treated with rust inhibitors and there was a sensitive waterway nearby. A temporary pond would have to be built in the parking lot to hold close to 200,000 gallons of treated water. With parking space already an issue and the time and effort needed to build such a pond freezing the 2- 12″ lines was the only option. The contractor wanted 2 – 12″ Accu Jackets in 1 day but had to use copper coils due to time constraints.

COB was able to assemble the double freeze equipment in a day and were able to be onsite to help get the setup done properly. The freeze was started after working hours of the facility and went on thru the night and was completed early the next morning. Valves were successfully replaced with only a small amount of water left between the ice plugs and the valves to deal with.

Courtesy Meridian Mechanical Orlando, FL