Remote (long Distance) Weld Purge Monitor.

Measuring accurately down to 10 ppm. With an internal electro-mechanical pump, battery or power driven with PurgeNet.

PurgEye®

1000 Remote Sensing Head can be fitted onto a mechanical or

inflatable purging system, directly at the weld location and will measure

oxygen level in the purge gas and transmit the information electronically to

the monitor up to 1 km away. With this capability, operators can obtain an

instantaneous and correct weld purge reading no matter how far they are from

the weld and be certain that the joint will not be adversely affected by

oxidation.

Measuring down to 10 ppm as far as 1 km away

When welding joints in long tube line or pipeline sections, it may not be practical to measure the purge gas exhaust close to the weld.

Measuring purge gas exiting in the joint gap is also unsatisfactory because of the oxygen being drawn in from outside and other variable factors.

A sensing head that can be fitted onto the purging system, directly at the weld location and will measure oxygen level in the purge gas and transmit the information electronically to the remote monitor and operator that may be up to 1 km away.

In this way, the operator can be certain that the weld purge reading is correct and that the joint will not be adversely affected by oxidation.

Portable ‘handy’ Purge Monitor, reading from 1000 ppm down to 1 ppm (accurate to 10 ppm).

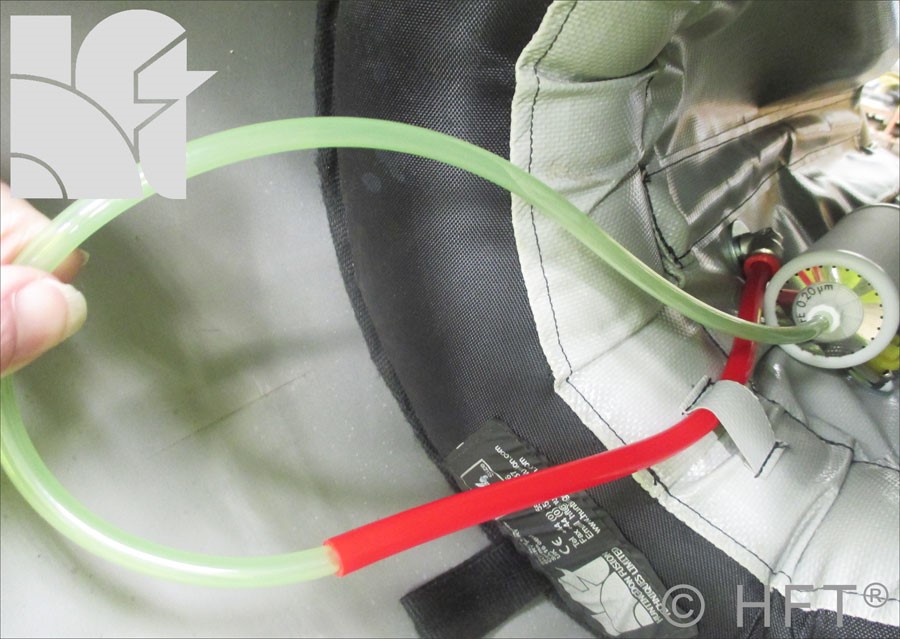

The PurgEye® 1000 Remote, with PurgeNet™ is equipped with a stainless-steel sensing head, which connects onto any Inflatable or mechanical Tube, Pipe and Pipeline Weld Purging System, producing accurate readings up to 1 km away from the weld.

The sensing head and the integral electro-mechanical pump are powered by the data cable, so only one cable is required. The sensor head is small enough to fit inside pipes from 1” (25 mm) diameter, upwards and is easily maneuvered through pipes.

Weld Purge Monitoring with PurgeNet™

The PurgEye® 1000 has been developed with a sensing head that can be fitted onto the Tube, Pipe and Pipeline Weld Purging System, directly at the weld location and moved from joint to joint. The new, fast response, zirconia oxygen sensor will measure oxygen level in the purge gas and transmit the information electronically to the monitor, up to 1 km away.

PurgeNet ™

The PurgEye ® 1000 comes complete with PurgeNet™, which can control Automatic Welding Systems as well as Orbital Welders, causing them to switch on and off for example when oxygen level rises too high or falls too low.

PurgeAlarm ™

The IP66 Rated (Environmental Protected) PurgeAlarm™ displays a red indicator, if the monitor reading has a greater value than the alarm threshold set by the user.

An optional green indicator can be fitted above the standard red indicator and will illuminate if the reading has a value lower than the alarm threshold set by the user. A sounder is available as an option to provide an audible alarm instead of the red light.

PurgeNet™ also works with PurgeLog™ to easily transfer weld purge data for Quality Control purposes.

The Argweld® PurgEye® 1000 Remote Weld Purge Monitor® comes with a handheld display, a sensor head hermetically sealed inside a small round stainless steel tube and a 10 m lead as standard.

Optional Docking Station for charging the battery if required. The unit will run from 100 – 250 volts, 50 hz supply.

Other features of the PurgEye® 1000:

- Optional 100 m reel of outdoor cable with locking connectors.

- Reels of extension cable can be connected together to make longer leads up to 1 km.

- Shorter or longer lengths can be supplied to order to suit application.

- PurgEye® 1000 display, battery or mains powered.

Suitable for fitting to mechanical or inflatable purging systems for 1” diameter pipe and larger. - The head will be powered from the data cable, so only one cable is required.

Technical Data and Specification

Measuring range from 1,000 ppm down to 1 ppm (accurate to 10 ppm).

The PurgEye® 1000 Remote also supports the following:

- Remote sensor head including electro-mechanical pump.

- Two user settable limits for alarm and process control.

- Relay contacts are included for monitoring the oxygen level. The contacts are no/nc (Normally open/normally closed) and volt free. They can be used to activate an alarm or switch a welding machine off and on again when the oxygen level rises above or falls below preset limits.

- Sounder for out of range oxygen readings.

- Key tones, to confirm button presses.

- RS-232 port for connecting to a personal computer (PC).

- Data logging facility, via PC.

- Machine status input (for data logging).

- Small, light and portable.

- Selectable display and language.

Range: 10 – 1000 ppm

Accuracy : + 25 ppm

Warm-up time: 2 minutes

Response time: 30 seconds

Reproducibility: < 15 ppm

Power consumption: Max. 18V

Use only weld purge hose leak tight quick disconnect fittings suitable for connecting 6 mm OD polyurethane tubing. Do not try to use other diameter tubing because it will not seal properly and will end up causing leaks.

The PurgEye® 1000 Remote Weld Purge Monitor® is simple to use, real plug and play.

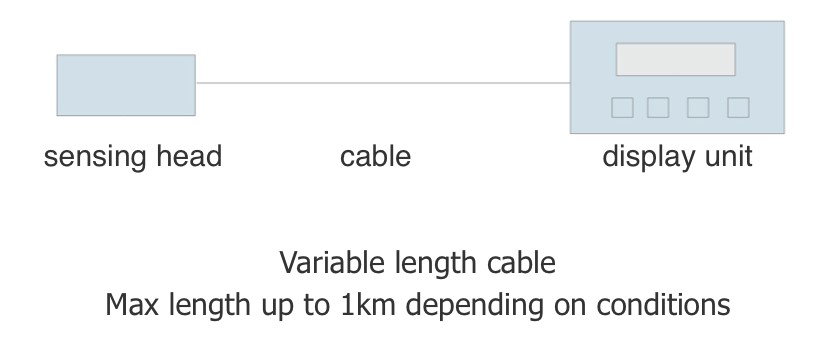

The sensor A is connected to the exhaust of the purging device, which is located directly at the weld site.

The exhaust purge gas flows through tube A and is measured by the remote sensing unit B, which sends the results electronically back to the display unit C.

The sensing head B can be supplied with fixing brackets so that it can be fitted to an internal pipe clamp with purging seals or stand alone pipe weld purging system.