ARGWELD® Purge Monitors

PurgEye™100 WELD PURGE MONITORSThe all-new PurgEye™ 100 Purge Monitors are the most advanced purge monitor of its kind from the makers of the best-selling MK V Purge Monitor. This new unit, like the earlier MK V models, is small, portable, easy to use and reliable. It will monitor O2 levels down to 0.01% (100 PPM) with a high degree of accuracy and comes complete with a stainless steel probe, 6 ft rubber tubing, aspirator bulb and carrying strap in a custom foam-lined case. It can be used in a continuous monitoring mode by connecting the tubing to an exhaust port of a purging device or enclosure and allowing the gas to flow freely over the sensor, or it can be used in a sampling mode by inserting the stainless steel probe into the area being purged or to an exhaust and using the aspirator bulb to initiate the flow across the sensor. The Argweld® product line has led the industry in cutting edge weld purging technology for over 30 years, and continues the tradition with the new PurgEye™ 100 Purge Monitors unit that offers even greater accuracy and unmatched features. The Argweld® PurgEye™ 100 is specifically designed and built for welding applications to give accurate readings at the low O2 levels required for weld purging. In fact, the PurgEye™ 100 is significantly more accurate than any purge monitor of its kind. Don’t risk your welds with inferior purge monitors or O2 sensors and monitors designed for confined space or medical applications that are inaccurate at lower O2 levels. |

Accurately measuring down to 10 ppm

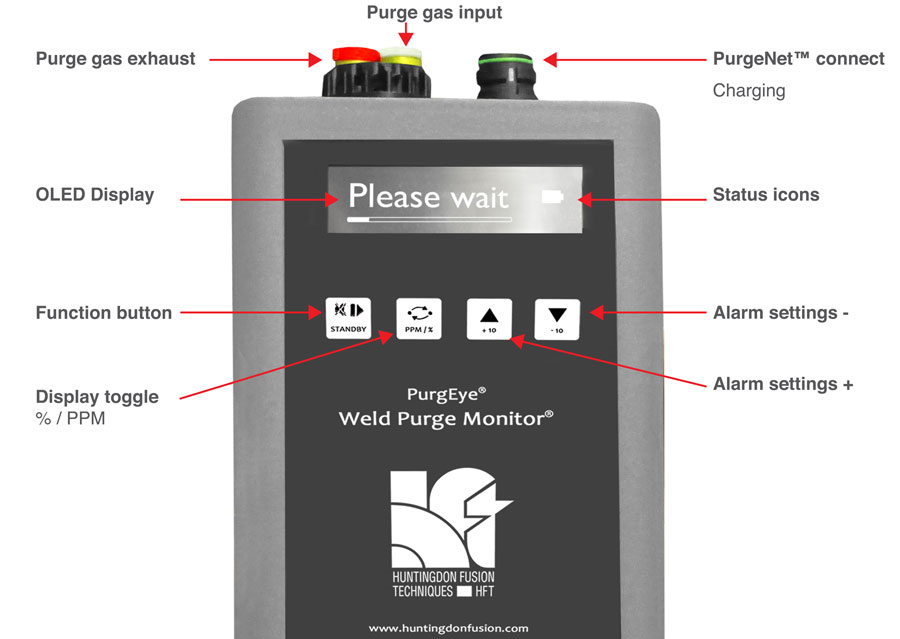

PurgEye 200 Purge MonitorsNow with an OLED display, the PurgEye ® 200 Weld Purge Monitor gives sharper, brighter and clearer readings for viewing at longer distances than before. The OLED display is mainly symbol based, which means the menus are easily understandable regardless of which languages the user speaks. The handy PurgEye 200 is battery or power driven, with charging carried out from a dock (optional). Battery life is up to 10 hours. The PurgEye 200 faster response and a long-life sensor. It also has loud, pre-settable audio alarms for rising or falling oxygen levels between 1 and 999 ppm as well as alarm + and – buttons for displaying threshold oxygen settings, In addition, there is an alarm mute as well as flow detection for accurate reading of gas samples. The PurgEye 200 also comes complete with leak tight connect / disconnect gas hose connections. The PurgEye 200 features PurgeNet ™, allowing the addition of standard accessories that will allow the Weld Purge Monitor to be linked with automatic welding machines such as orbital welders, a traffic light accessory to give visual indication of the Purge process and final a dew point meter. As with all other HFT products, the Argweld PurgEye 200 Weld Purge Monitors are always in stock and available for immediate delivery Worldwide. |

|

|

|

|

|

|

PurgEye 1000 RemoteLong Distance Weld Purge Monitor |

Measuring Down to 1 ppm! |

Use the right tool for the job!

PurgEye® 300 “NANO” Purge Monitors

PurgEye® 300 “NANO” Purge Monitors

Measuring accurately down to 10 ppm. With an internal electro-mechanical pump, battery or power driven with .PurgEye® 1000 Remote Sensing Head can be fitted onto a mechanical or inflatable purging system, directly at the weld location and will measure oxygen level in the purge gas and transmit the information electronically to the monitor up to 1 km away. With this capability, operators can obtain an instantaneous and correct weld purge reading no matter how far they are from the weld and be certain that the joint will not be adversely affected by oxidation.

Measuring accurately down to 10 ppm. With an internal electro-mechanical pump, battery or power driven with .PurgEye® 1000 Remote Sensing Head can be fitted onto a mechanical or inflatable purging system, directly at the weld location and will measure oxygen level in the purge gas and transmit the information electronically to the monitor up to 1 km away. With this capability, operators can obtain an instantaneous and correct weld purge reading no matter how far they are from the weld and be certain that the joint will not be adversely affected by oxidation.