Purge Bladder Systems

Argweld® Inflatable Purge Bladder Systems are the most effective systems available for pipe purging. The system is pulled into position and inert gas is used to inflate the bladders (dams) which provide a 100% airtight seal on either side of the weld joint, after which the pressure in the system opens the purge valve and the gas purges the space between the bladders ensuring a clean, even penetration bead. Once the weld is completed, the gas is turned off and the bladders are deflated so the system can be pulled through the pipe to the next weld. These systems are specifically designed to be easily pulled into position through long sections of pipe and around elbows without the risk of getting jammed or stuck in the pipe.

Effective weld purging is only achieved by making sure that oxygen is displaced from the purge zone prior to and during welding. Any residual oxygen can cause significant loss of corrosion resistance and a reduction in joint strength. It is therefore essential to seal the pipe either side of the joint and maintain this seal … Continue reading

Why choose Argweld®?

Click here to find out more about how Argweld® pipe purging equipment stacks up against other purging methods.

Cost comparison: Argweld® Quick-Purge™ VS. pre-formed paper dams

Click here to see how much you can save!

ARGWELD® Multi-Port Purge Bladders ARGWELD® Multi-Port Purge Bladders

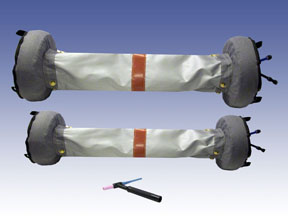

The latest version of the Argweld® Purge Bladder Systems is the Tandem Purge Bladders now offers multiple inlet / exhaust ports for faster, more effective weld purging. The user is able to increase the gas flow without fear of over-pressurizing the weld by utilizing additional inlets / exhausts while maintaining a non-interference seal on the pipe ID. The multiple exhaust ports can also be utilized to accommodate a pressure gauge to monitor gas pressure for orbital welding. This is an important new feature added to the already popular Argweld® Tandem Purge Bladders. Available in sizes for 1.5” through 7” pipe. |

ARGWELD® Quick-Purge™ |

Purge Bladder Systems The Quick-Purge™ systems are specifically designed for larger diameter pipe. They offer a primary gas intake and an auxiliary line which gives the welder the ability to pump as much or as little gas into the purge area as needed for a fast weld with the appropriate amount of pressure. This is particularly important when welding larger bore pipe. The tandem inflatable bladders are connected by a sleeve instead of a spinal hose which serves 2 critical purposes:

- The sleeve contains flexible supports that maintain the shape of the larger bladders even when deflated so that when they are pulled into position and the gas is turned on, they automatically seat themselves properly in the pipe and provide a 100% airtight seal on either side of the weld every time. The support of the sleeve prevents the bladders from folding over or getting jammed up while providing enough flexibility to allow the system to be pulled through long sections of pipe and around elbows with ease.

- The sleeve design also further reduces the amount of air volume that needs to be purged, which dramatically speeds up the process. Not only do the inflatable dams isolate the section of pipe around the weld joint for purging, the sleeve eliminates the majority of volume between the dams, making this the fastest purge system available. In side-by-side comparison studies Quick-Purge™ systems have proven to be up to 8 times faster than foam, paper or other conventional pipe purging methods. These systems are rugged and durable, designed to be used over and over to produce hundreds of clean, high-quality welds. The sleeve and inner portions of the bladders are all made from heat-resistant silicone material to withstand the high temperatures encountered in the welding process. Available for sizes 8” and up.

Argweld® Heat-Resistant Quick-Purge™ Systems Argweld® Heat-Resistant Quick-Purge™ Systems

Purge Bladder Systems based on the Quick-Purge™ design, modified with longer sleeves and completely encased in heat-resistant materials to handle the higher temperatures encountered with pre-heat welding processes on chrome and other exotic pipe materials. |

FEATURES

Compared to other methods of gas purging for pipe welding the Argweld® Purge Bladder systems have a number of distinct advantages that lead to consistently clean welds and significant savings.

- Reliable. A good purge can be achieved and maintained every time without the fear of the dams becoming dislodged or compromised during the weld process.

- Faster. These systems are the fastest method of pipe purging by far with no time wasted building, taping or gluing dams in place, and no time wasted purging long sections of pipe. Due to their superior design, the purge time required is up to 8 times faster than foam, paper or other conventional purging methods. For example, an 8” pipe can be purged to less than 1% O2 in less than 60 seconds and a 12” pipe in about 90 seconds.

- Use less inert gas. Argweld® purge systems also offer huge savings from reduced gas consumption for weld purging. They typically use less than 1/3 of the amount of gas required with other types of purge dams.

- Easy to use. Argweld® purge bladders greatly simplify the process of inert gas purging. With minimal training bright shiny welds that pass inspection can be achieved in no time.