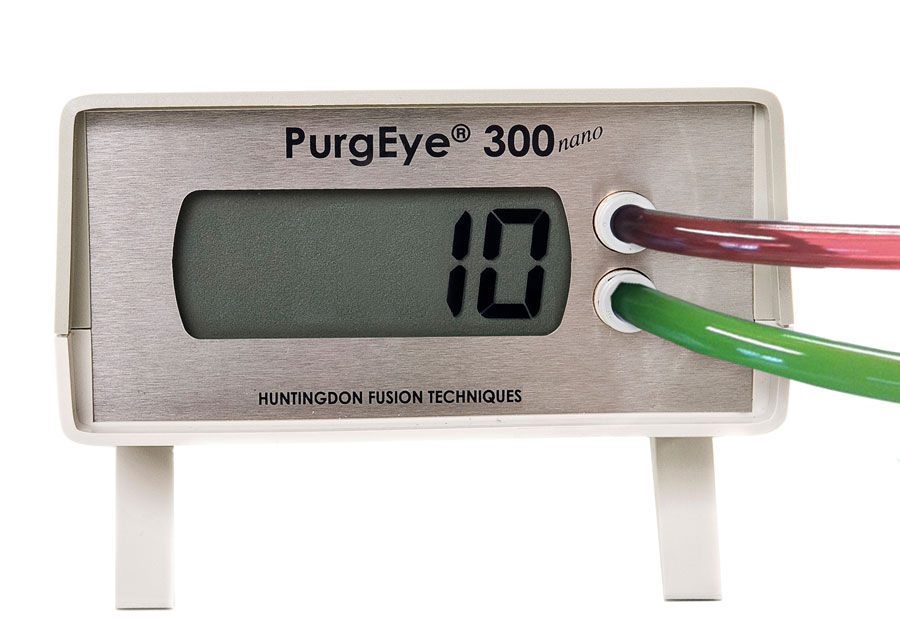

PurgEye® Nano

This weeks Product Feature is our PurgEye® Nano, the World’s first and only low cost, no frills, Weld Purge Monitor® that measures down to 1 ppm (accurate to 10 ppm).

With a large alpha-numeric display, the Argweld® PurgEye Nano measures very accurately from 1000 ppm down to 10 ppm

Low Cost

The PurgEye Nano is the industry’s most affordable Weld Purge Monitor® capable of accurately reading O2 levels down to 10 Parts Per Million (PPM). This unit is specifically designed for purging applications involving ultra-high purity stainless steel, titanium, zirconium, and nickel alloy, etc. This no-frills, highly accurate monitor is a simplified version of the PurgEye 300 Weld Purge Monitor™.

Key features and benefits:

- ‘Plug and use’ monitor.

- Unique long life sensor.

- Sensor warm up time is less than 60 seconds.

- Leak tight connectors for weld purge hoses.

- Large alpha numeric display.

- Calibration inexpensive and only a few days turnaround.