During purging welders need to measure the oxygen content but also need to measure the ‘dew point’.

The dewpoint is the temperature where condensation begins and water will condense on the material being welded. This can affect the weld properties significantly.

The Dew Point Sensor can be used in conjunction with the range of 10 ppm Weld Purge Monitors, so rather than purchasing a separate, expensive Dew Point Meter, the Dew Point Sensor connects to the PurgEye Weld Purge Monitor via the PurgeNet™ lead.

PurgEye 200, PurgEYE 500 Desk, PurgEye 600, PurgEye 1000, PurgEye Site

Connection is made via the PurgeNet lead that is supplied as standard with all models.

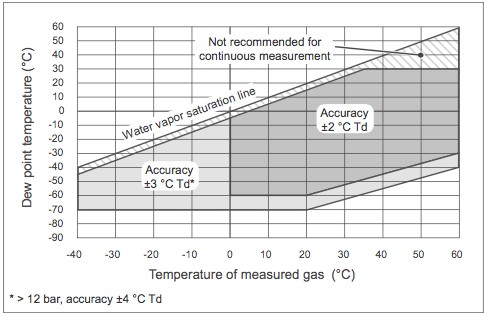

SPECIFICATION:- Measurement Range (@20˚C and 100 mbara)?

300 to 50,000 ppm(v)

(600 to 200,000 ppm(v) @ 50˚C) - Accuracy (@ 20˚C and 1000mbara)

30 ppm + 10% of measured value # - Response time (t90)

minutes for decreasing dew point

seconds for increasing dew point # - Power Requirement

1 watts, powered from o2M (with PurgeNet™) - Output

Dew point data will be output to supporting Weld Purge Monitor with PurgeNet™ for display (and logging on compatible models) - Medium temperature.

# This will be heavily dependent on pipe length, material, ambient temperature etc. (Pipe lengths must be kept to a minimum). However, purge times will likely be significantly longer than the response time.